Superior

Cavity Batten System

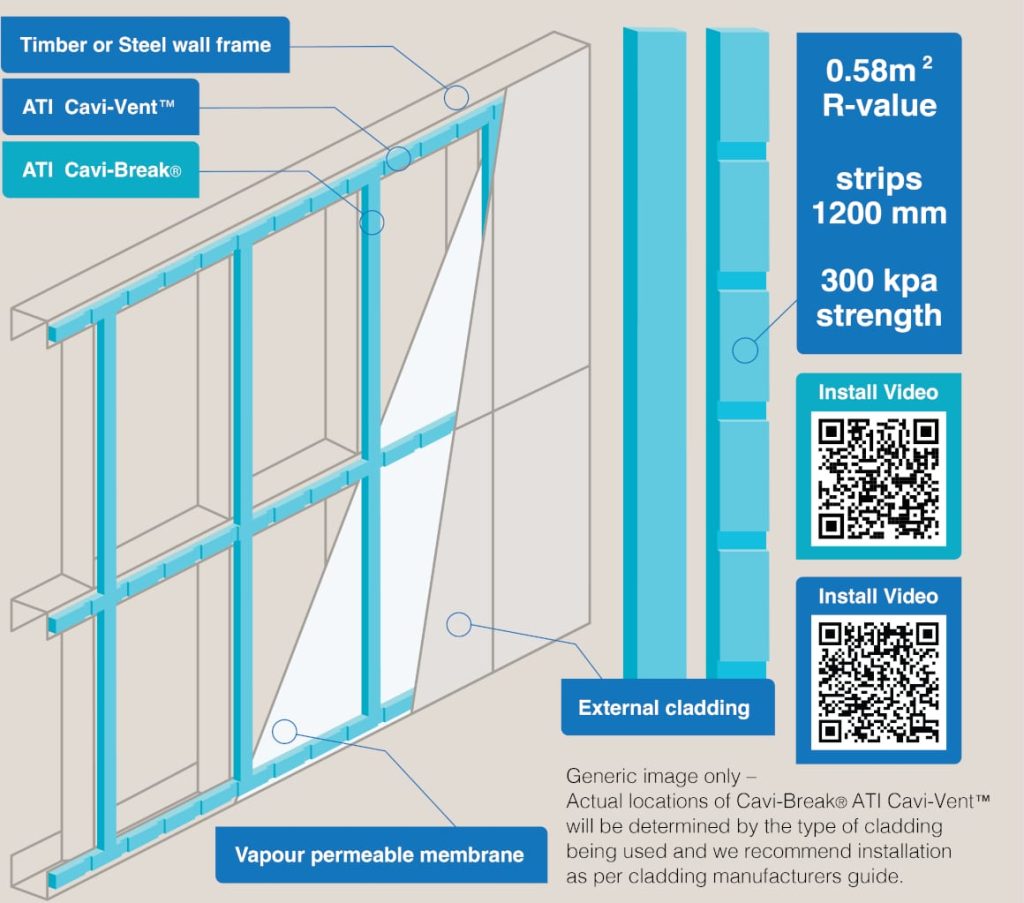

Cavi-Break & Cavi-Vent are the all-in-one thermal break cavity batten system delivering improved thermal breaks, effective cavity ventilation, reliable cavity closure, and an easy and cost effective installation for both residential and commercial construction.

The ATI Cavi-System

Meet and exceed 7 Star and NCC 2025 requirements

Experience our innovative thermal break cavity batten products, working seamlessly as a system to provide superior building energy efficiency and durability.

Designed to meet and exceed 7 Star and NCC 2025 requirements for thermal efficiency, cavity ventilation and condensation management.

Cavi-Break® Cavity Batten

The Essential Thermal Break Cavity Batten

- High-performance thermal barrier: Effectively reduces heat transfer between external cladding and the frame.

- Easy installation: Self-adhesive backing ensures quick and secure application.

- Versatile compatibility: Suitable for both steel and timber frame construction.

Cavi-Vent® Cavity Drainage Batten

Ventilated Cavity Drainage Batten, Cavity Closer and Thermal Break

- Dual functionality: Acts as both a ventilated 20mm cavity drainage batten and a thermal break.

- Superior moisture management: Promotes airflow and prevents condensation, reducing the risk of rot, mildew and mould.

- Effective pest control: Closes the cavity, preventing vermin infestation.

ATI Cavity System Benefits:

- Achieve true 7 Star Energy Efficiency: Ease of Compliance. Significantly reduce thermal bridging for optimal performance.

- Proper Ventilation and Moisture Control: Create a healthy and long-lasting structure with ventilation and moisture control.

- Simplified Installation:

Easy application, saving you time and effort. - Ideal for:

- Steel and timber framing

- Residential and commercial construction

- All types of lightweight cladding

Choose Australian Thermal Industries’ Cavi-System for a comprehensive NCC compliance solution that delivers exceptional thermal break performance results.

Easy and Quick Install

Watch the Cavi-System installation in action at Brooks Builders’ child care building site

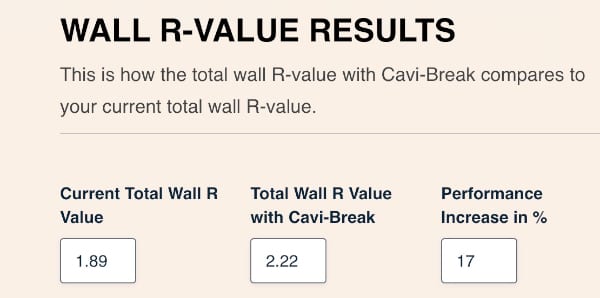

Thermal Performance

R-value of 0.58 m² K/W, exceeding the NCC minimum R-Value requirement of 0.2 m² K/W nearly three times

ATI’s Cavi-Break® and Cavi-Vent® Strips are an advanced thermal break and condensation management solution.

With the upcoming NCC 2025 changes, this will become even more important.

Benefits for Builders

There are many benefits for residential and light commercial builders using the Cavi-Break® and Cavi-Vent® System

- Lightweight for easy handling

- Easy to cut & quick to install

- 45mm x 20mm based on industry needs

- Convenient 1200mm length

- Will not compress (300KPa strength)

- Self-adhesive that really works

- 70 Cavi-Break or Cavi-Vent Strips (84 linear meters) per carton

- Superior condensation management

- Superior thermal properties (R-value of 0.58m²)

- 10 Year Warranty

Cavi-Break® Strips

Industry-leading thermal break and cavity batten for residential and light commercial construction

Ideal for use with both steel and timber framing, ATI Cavi-Break® Strip is the thermal break cavity batten solution Australian builders have been looking for to comply with the increased NCC 2025 thermal performance requirements.

- R-value of 0.58m² K/W.Exceeding the minimum National Construction Code (NCC) by almost three times.

- Developed in close consultation with industry experts and leading builders to better suit their needs and save valuable time and money.

- Supplied in convenient 1200mm strips to suit a typical 2400mm ceiling height.

- Each carton contains 70 Cavi-Break Strips or 84 linear meters, enough to batten up no less than 35 studs, but still is lightweight to carry.

For More Information

Cavi-Vent® Strips

Industry-leading ventilated cavity drainage batten, cavity closer and thermal break

To easily and effectively comply with the new NCC 2025 cavity ventilation and condensation management requirements, the castellated ATI Cavi-Vent® Strip is the must have solution for Australian builders.

- Save valuable time and money. Ease of handling and install (1/10th the weight of timber).

- Each carton contains 70 strips, totalling 84 linear meters.

- 1200mm length ideal for 600mm stud centre builds.

For More information

NCC 2025 Changes to Thermal Breaks and Condensation Management: What You Need to Know

Using ATI’s Cavi-Break® and Cavi-Vent® systems makes it easy to stay ahead. Our solutions streamline compliance with current standards and are designed to meet NCC 2025 requirements for thermal efficiency, cavity ventilation and condensation management, ensuring your projects are built to best practice.

What do the NCC 2025 updates mean for thermal breaks, wall cavity ventilation, and the construction industry at large?

How many thermal break strips do you need?

We’ve created a Usage Estimator for your convenience to estimate how many cavity batten strips are needed for your project.

Call 1300 430 949 or send us a message for a free sample or any other question.

Customer Stories

Buy From Our Resellers

Order from our reseller partners and we dispatch same day

The ATI Story

Revolutionising Australian Building Efficiency

Australian Thermal Industries (ATI) specialises in the production and supply of high-performance products that enhance energy efficiency in new Australian homes.

With a keen eye on innovation and strategic procurement, ATI presents Cavi-Break® and Cavi-Vent®, standout products developed to enhance thermal mitigation for steel framing and to provide dependable thermal break cavity battens for timber frames, ensuring superior ventilation and condensation management and bolstering building integrity.

Contact us today

Cavi-Break® and Cavi-Vent® Thermal Break Strips are a lightweight, easy to apply and economical product that exceeds the minimum National Construction Code (NCC) requirement by almost 3 times.

Contact us today so that we can work with you on your project.

Did you know

ATI donates 1% of the sales revenue to the HIA Charitable Foundation (HIACF), which works to improve health and welfare outcomes in the housing industry, including mental health issues.