ATI Cavi-Break Strip®

Cavity Batten and Thermal Break Strip | Product Info

Multi-Use Cavi-Break® Thermal Break Strip

For better building outcomes

Thermal break cavity battens, such as Cavi-Break, are innovative insulation solutions placed between the building’s external framing and exterior cladding. They are designed to mitigate thermal bridging by reducing the transfer of heat and cold, effectively enhancing the overall energy efficiency of Australian homes and light commercial buildings.

ATI’s Cavi-Break® Strip Thermal Break & Cavity Batten is the best thermal break cavity batten strip for residential & commercial external cladding, exceeding NCC code three times. It can be very easily installed – no tools needed.

Leading specs

The industry-leading ATI Cavi-Break Strip is a low conductive and flame retardant thermal break strip and cavity batten that has been fully tested for Thermal R value compliance to exceed NCC standards three times while making handling and installation much easier for builders.

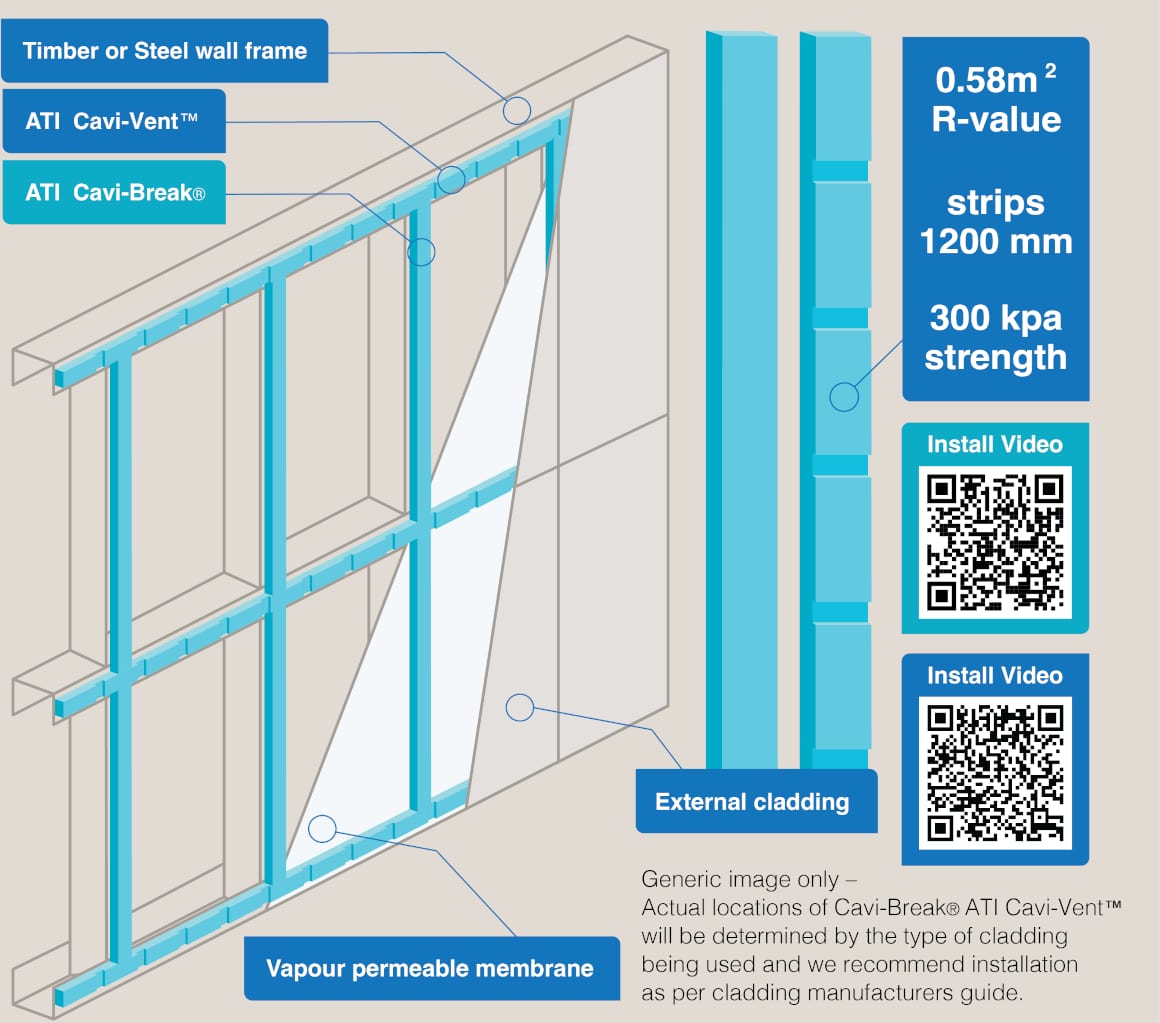

Use in timber and steel construction

Cavi-Break, when utilised in timber construction, is strategically positioned as a thermal break cavity batten between the wrapped timber frame and the external cladding. This arrangement provides an essential spacing that promotes natural airflow and enables effective condensation management, thereby contributing to the longevity of the structure.

In steel frame applications, the Cavi-Break Strip excels by creating an enhanced thermal barrier at the interfaces between external cladding and the steel frame.

Input from industry experts

Our product has been developed in close consultation with industry experts and leading builders to better suit their needs and save valuable time on residential and light commercial construction projects.

It is supplied in convenient 1200mm strips to suit a typical 2400mm ceiling height.

ATI Cavi-Break Strip is ideal for use with a wide range of lightweight cladding materials, including hardwood, fibre cement, fibreboard, aluminium, stone, metal and vinyl.

Find more information in the following documents and on our Downloads page

ATI Cavi-Break® Strip

For Smarter Building Solutions

- Effortless Handling: Our lightweight design ensures ease of installation.

- No Dust Cutting: Easy to cut with hand tools, maintaining a clean work environment.

- Optimized Dimensions: Pre-sized to industry preferences for immediate use without additional trimming.

- Eco-Friendly Packaging: Each box contains 70 strips in 100% recyclable cardboard, designed for efficient transport.

- Instant Information: Access product information details quickly via the QR Code on each carton.

- Intuitive Installation: QR guides on each strip and carton make installation straightforward.

- Proven Performance: Complies with NCC standards. Thermal break with a high r-value of 0.58m² K/W for superior insulation.

- Built to Last: Waterproof, fire-retardant, and resistant to mould and termites, ensuring long-lasting quality.

- Trusted Quality: We stand behind our product with a ten-year warranty.

Timber Frame Application

Optimal timber framing performance

Achieve optimal timber framing thermal break performance with ATI Cavi-Break Strip.

Improve the quality of your timber frame construction with ATI Cavi-Break Strip, the intelligent cavity batten solution designed to promote best building practises.

In contrast to steel, timber is susceptible to moisture-related challenges such as condensation buildup, which can discreetly compromise a structure’s structural integrity by introducing the risk of mould growth, rot, and degradation. The ATI Cavi-Break Strip efficiently generates a 20mm gap for condensation management, an important feature that is sometimes overlooked in traditional cladding.

The strip affixes seamlessly to sarking or vapour barriers, fostering essential airflow that helps manage condensation buildup. Investing in moisture management is crucial for the long-term sustainability of your projects, particularly given the distinct climate conditions in Australia.

The ATI Cavi-Break Strip streamlines construction with its straightforward application and precise fit, offering a superior alternative to bulkier options such as plywood and H3 treated pine battens. This reduces both material waste and installation time. Choosing our strip means you’re not just constructing with immediate efficiency in mind but also fortifying your wood frame projects for enduring stability and resilience.

Frequently Asked Questions

Answers to the most common Cavi-Break® and Cavi-Vent™ questions, ensuring you have all the information about our innovative thermal break and cavity ventilation system.

What is the purpose of a thermal break?

The purpose of thermal break materials and systems (thermal breaks) is to reduce the impact of thermal bridging by preventing conductive heat flow through the thermal envelope. Thermal breaks keep the heat in and push the dew point out.

What is a thermal break strip?

A thermal break is required by the National Construction Code (NCC) between any external cladding material and steel framing. They increase energy efficiency by preventing heat gain or energy loss and they keep condesation at bay to prevent mould and timber rot.

ATI Cavi-Break® Strip is a thermal batten barrier product that enhances the energy efficiency of Australian homes and light commercial buildings built with steel or timber framing. It creates a higher thermal barrier wherever external cladding is fixed to steel or timber frames. The thermal properties prevent condensation formation and therefore prevent moisture problems.

ATI Cavi-Vent™ Strip is a ventilated thermal cavity-closer batten that prevents condensation formation and increases ventilation to dry out the exterior wall cavity, therefore preventing moisture problems and rot.

Is a thermal break generally necessary?

Thermal breaks play a crucial role in preventing condensation issues that can lead to mould and rot, as well as improving energy efficiency in buildings.

In timber framed structures, a drop in the framing member’s temperature below the dew point can result in condensation formation, especially in air-conditioned buildings, which in turn can lead to mould and rot.

Similarly, in steel framing, the absence of a thermal break can cause significant energy loss through all steel framing members, significantly diminishing the overall energy efficiency of the building.

How does ATI Cavi-Break Strip work to improve energy efficiency in steel-framed homes and light commercial buildings?

ATI Cavi-Break Strip works by reducing more of the heat transfer through the steel frame, which can significantly improve the energy efficiency of steel-framed homes and light commercial buildings. By creating a higher thermal barrier wherever external cladding contacts steel frames, ATI Cavi-Break Strip helps reduce heat loss in winter and heat gain in summer.

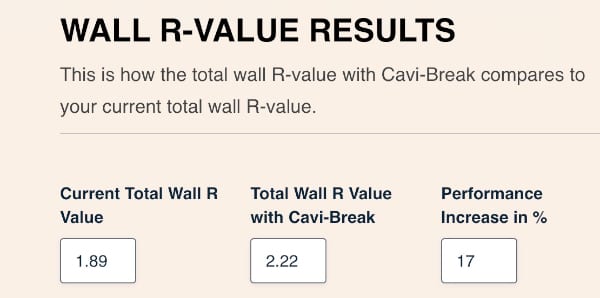

The thermal performance is better than most traditional construction methods used – see R-Value comparisons.

Try our Total Wall R-Value Calculator to see the energy efficiency improvements yourself.

Where can I buy the Cavi-Break Thermal Cavity Batten Strip?

ATI Cavi-Break Strip can be found at various building supplies stockists across Australia as special order. Customers can check the list of stockists on our website or contact us directly for assistance.

We can also directly delivere to your building site for convenience. Get an Express Quote for included delivery to your site today.

Consult our where to buy page.

How does ATI Cavi-Break Strip save time and reduce waste during installation?

ATI Cavi-Break Strip saves time and reduces waste during installation by being light and easy to handle and can be cut using hand tools. It is supplied in convenient 1200mm lengths, which reduce trimming time for standard 2400mm ceiling heights. The product is self-adhesive, eliminating the need for applying additional adhesives or pinning to frame prior to cladding.

Can Cavi-Break be used in both residential and commercial buildings?

Absolutely! The Cavi-Break is versatile and effective in both residential and commercial settings, ensuring optimal thermal performance across a variety of building types.

It can be used in timber and steel construction for most leightweight cladding. Make sure to check the Download Section to learn more about the application with different cladding types.

Also read some of our builders experiences with different construction types in our News section

What type of cladding is Cavi-Break Strip compatible with?

Available in 1200mm strips, Cavi-Break is compatible with an array of cladding materials such as

– hardwood

– fibre cement

– aluminium

– and vinyl

This compatibility ensures a versatile solution or a multitude of construction requirements. You can find more information in the Download section.

What are the benefits of using ATI Cavi-Break Strip for builders, fabricators, and cladding suppliers?

The benefits of using ATI Cavi-Break Strip include easy handling and installation, high R-value that far exceeds NCC requirements, non-compression, and self-adhesive properties. It is supplied in convenient 1200mm lengths, reduces waste during installation, and is suitable for use with a wide range of lightweight cladding materials.

What is the R-value of ATI Cavi-Break Strip and how does it compare to NCC requirements?

The R-value of ATI Cavi-Break Strip is 0.58m² K/W, which is almost three times higher than the minimum NCC requirement of R 0.2m² K/W. This means that using ATI Cavi-Break Strip can significantly exceed NCC requirements for thermal insulation in steel-framed homes and contributes to the overall R value of external wall construction.

The additional R-value contribution can mean reduced wall insulation to meet 6 or 7 star rating requirements – in some cases leading to the ATI Cavi-Break Strip being cost neutral for overall savings.

Can ATI Cavi-Break Strips be used as a cavity batten for timber framing?

ATI Cavi-Break Strips can also be used as a cavity batten for timber framing by being applied on top of breathable sarking to create the cavity to allow moisture and water vapour to dissipate. It also saves time and reduces wastage during installation as it is faster and easier to install than alternatives like plywood or timber.

Research work by BRANZ in New Zealand, where they are significantly more advanced in condensation management than Australia, indicates that narrow cavities around 6mm – 12mm do not have enough separation in ‘real world’ situations because of the potential for bulging to occur from the bulk insulation in the wall, leading to bridging of the cavity.

Cavities more than 20mm in depth provide no more advantage in terms of ventilation, so a 20mm cavity is seen to be the most pragmatic. This also lines up with the requirement in the NCC for timber thermal breaks to be a minimum of 20mm thick.

Does the ATI Cavi-Break Strip also create the cavity behind the external cladding on steel frames?

Yes, by using the ATI Cavi-Break Strips, a proper cavity is created between the breathable wall sarking and the back of the external cladding. Leading cladding manufacturers strongly recommend a cavity between the sarking and the external cladding.

This is to allow any vapour that builds up within the wall to dissipate and prevent condensation forming on the back of the cladding, or plasterboard, and running to the bottom of the wall frame. The lack of any cavity has been shown to facilitate rotting of the bottom plate and frame, as well as growth of unhealthy mould inside the wall framing and eventually into the wall linings and external cladding.

Two solutions from one product.

What is the compressive strength of ATI Cavi-Break Strip?

The compressive strength of ATI Cavi-Break Strip is 300kPa, which ensures very straight wall and facade faces but also prevents fixings pulling through the cladding material.