This week, ATI had the opportunity to visit a large-scale residential project of approximately 470 homes, all set to utilise ATI’s Cavi-Break and Cavi-Vent products.

Walking through the site with the project manager was a great chance to see firsthand how our solutions are enhancing productivity and efficiency on-site.

Some of the feedback we’ve received

- Faster Installation: Installers are finding that scoring and snapping Cavi-Break strips, removing the backing tape, and adhering them to the building wrap over the steel frame is much faster than cutting and treating cut ends of pine thermal breaks, which also requires two installers, equipment and fasteners for fixing to the frame.

- Efficient Cladding Installation: The team is pre-drilling Weathertex Weathergroove 150 Smooth cladding on a flat surface before standing it for installation, then securing it through Cavi-Break/Vent into the steel frame. This method is efficient, and allows for precise installation. In contrast, using pine thermal breaks as structural battens to support cladding requires strict adherence to engineering and NCC requirements. While they can meet standards with proper design, precise installation is essential to maintain structural integrity.

- Reframing Steel Structures with Timber: A carpenter who recently moved up from Melbourne shared an interesting observation. He mentioned that while he used to install pine thermal breaks, he found it difficult to reconcile the idea of reframing a steel structure with timber. He noted that many homeowners may not be aware that, despite buying a ‘steel frame’ home, parts of it are essentially being reframed with timber during the installation of pine thermal breaks. This approach could undermine the perceived benefits of a steel-framed home.

- Reliable Fasteners: Carpenters were particularly happy with the Bremick 10g x 50mm CSK Head Self-Drilling Screw – a class 3 fastener without wings that avoids boring out holes in lighter gauge steel, a common issue. The 50mm length is ideal for the thickness of the cladding and 20mm thermal break.

- Minimising Waste: The ability to use small sections or offcuts of Cavi-Break and Cavi-Vent is a valuable advantage. We also discussed waste management for the backing strip tape. Our cartons have been designed with a tear-away strip that turns the top into a 350mm deep bin, making on-site clean-up easier.

- Interest in 2750mm lengths: Additionally, there was interest in 2750mm lengths for Cavi-Break and Cavi-Vent, which is something we’ve considered. While we initially thought 1200mm lengths would be optimal for storage, transport, and installation, we’re eager to hear your preferences.

What a fantastic day to learn

Overall, it was fantastic to see a large-scale builder opt for ATI’s Cavi-Break and Cavi-Vent for their non-compressibility, ease of trimming, and superior self-adhesive properties.

We’re always looking for feedback and input to further improve on-site performance and efficiency. Thanks for your insights!

Learn More

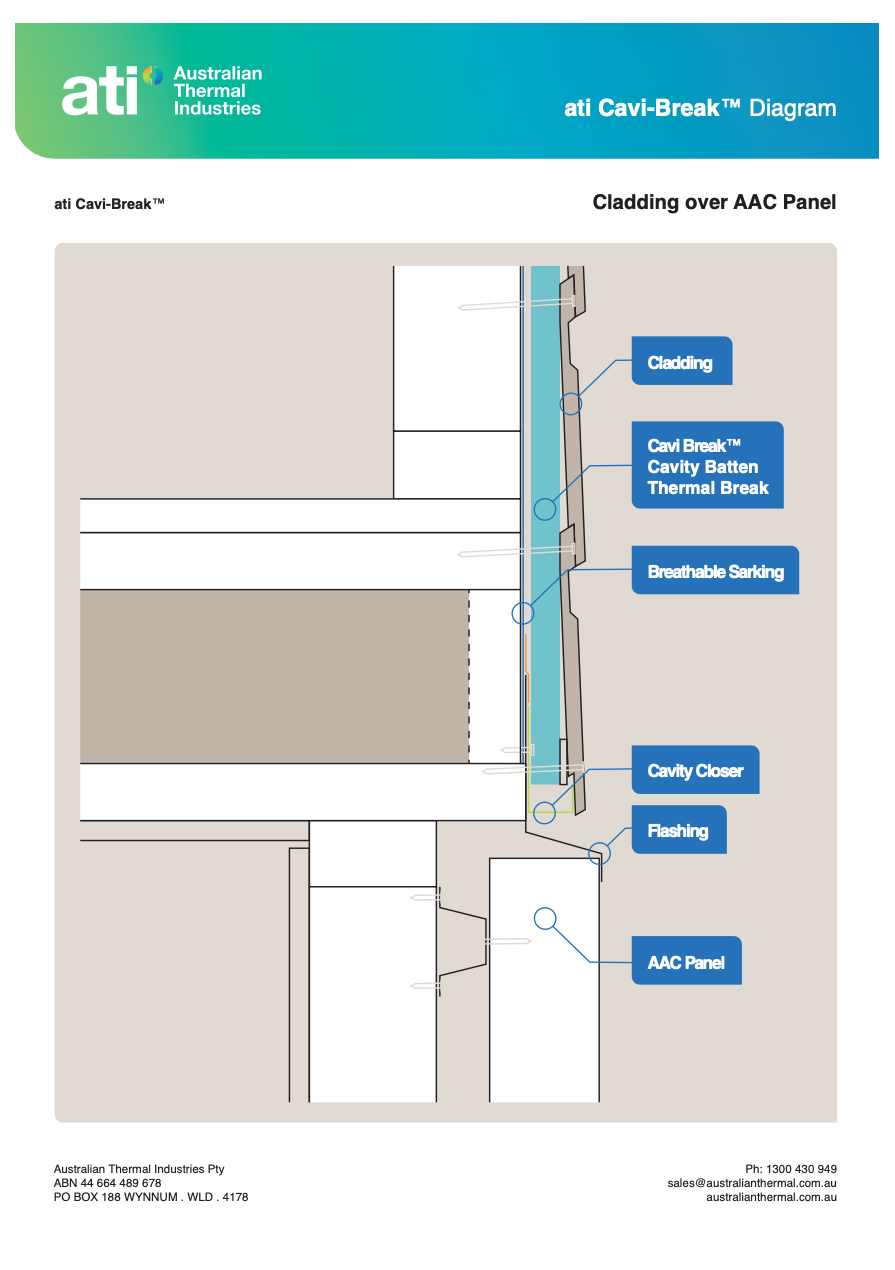

Wall Cavity Diagrams

See all our Wall Cavity Diagrams for different cladding types in our Downloads section.

Related Articles

Cavities Behind Lightweight Cladding: Problems, the Science and Best Practice

Exploring The Role of Thermal Breaks

Product Information

Cavi-Break® product page and brochure

Cavi-Vent® product page and brochure

Consult the ATI Downloads section for technical details

R-Value Calculator

Try our Wall R-Value Calculator to compare different cavity batten solutions

Purchase

Where to purchase – major building supplies stockists

Usage Estimator – calculate how many strips you need